WHAT SPEED SHOULD MY SAW BLADE SPIN AT?

When designing a timber cutting mill, machine or processor, the speed the saw blade runs at can be critical in whether or not the mill operates efficiently and effectively. Saw blade speeds can vary a lot depending on the type of timber, the cutting application and what kind of result you are looking to achieve from your processor. To make it simpler, we've put together a few key considerations below to help determine the optimum saw speed for your saw.

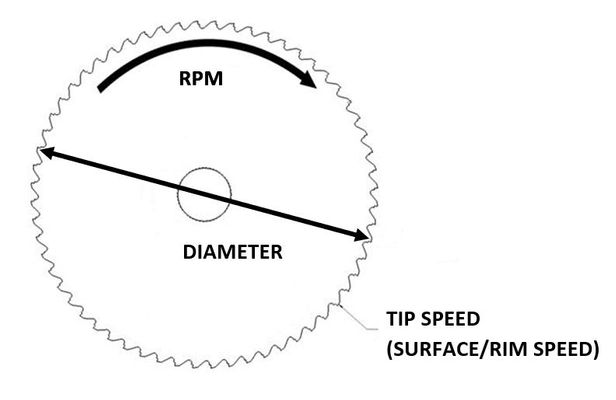

Saw blade speed can be expressed in either Revolutions Per Minute (RPM) or Tooth Surface Speed (usually measured in Metres Per Second, m/s). RPM and Tip Speed have a direct relationship depending on the size (diameter) of your saw blade.

In order to work out the optimum saw speed, you will need to take into account a few considerations which make a big difference:

WHAT MAKES A DIFFERENCE TO MY SAW SPEED?

Cutting application - will you be ripping or cross cutting? Are you needing fine trim cuts, or rough docking cuts for firewood?

What sort of timber will be cut? Hardwood or softwood? Green or Dry?

What production output are you needing to achieve? Is your saw needing to cut quickly for maximum output? Are quick cycle times required, or is accuracy more important?

How are you feeding the timber into the saw? Will the saw move to the timber, or the timber to the saw?

SAW TIP SPEED

The Tip Speed of a saw blade will ultimately determine how the blade performs in the cut*. In order to make it simple we have developed a list of recommended tip speed ranges for general timber cutting applications:

HARDWOOD - RIPPING CUTS: when ripping hardwood we recommend 50-70 m/s tooth speed, depending on the species, and whether it is GREEN or DRY.

HARDWOOD - CROSS CUTTING & DOCKING: Optimum tooth speed for docking hardwood is around 45-55 m/s – note that moisture content is less critical when doing docking cuts.

SOFTWOOD - RIPPING CUTS: softwood timbers can be sawn using tip speeds ranging from 45m/s for smaller portable sawmills, up to 80m/s for commercial precision guided production sawmills.

SOFTWOOD - CROSS CUTTING & DOCKING: Docking softwood timbers requires a tip speed ranging from 45-60 m/s.

PARTICLE BOARD & PLY BOARD: 50-70 m/s works well when performing panel sizing cuts to manufactured boards such as plyboard, chipboard, particle board and melamine.

HOW CAN I CALCULATE MY SHAFT SPEED (RPM)?

Shaft speed is directly related to the size of your saw blade and tip speed. As a rule, the larger your saw blade is, the slower it will spin to maintain the recommended tooth speed; conversely a smaller blade will spin a lot faster to achieve recommended tooth speeds. The Chart below is a quick reference to help you calculate the optimum RPM based on your Saw Diameter and recommended tip speed:

|

Saw Blade Diameter / Surface Speed / Revolutions Per Minute (RPM) Cross Reference |

||||||||||||||||

|

Rim Speed |

||||||||||||||||

|

Ø |

D |

Feet / Min |

4900 |

5900 |

6900 |

7900 |

8900 |

9800 |

10800 |

11800 |

12800 |

13800 |

14800 |

15700 |

16700 |

17700 |

|

inch |

mm |

Metres / Sec |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

|

4 |

100 |

|

4777 |

5732 |

6688 |

7643 |

8599 |

9554 |

10510 |

11465 |

12420 |

13376 |

14331 |

15287 |

16242 |

17197 |

|

6 |

150 |

R |

3185 |

3822 |

4459 |

5096 |

5732 |

6369 |

7006 |

7643 |

8280 |

8917 |

9554 |

10191 |

10828 |

11465 |

|

8 |

200 |

E |

2389 |

2866 |

3344 |

3822 |

4299 |

4777 |

5255 |

5732 |

6210 |

6688 |

7166 |

7643 |

8121 |

8599 |

|

10 |

250 |

V |

1911 |

2293 |

2675 |

3057 |

3439 |

3822 |

4204 |

4586 |

4968 |

5350 |

5732 |

6115 |

6497 |

6879 |

|

12 |

300 |

O |

1592 |

1911 |

2229 |

2548 |

2866 |

3185 |

3503 |

3822 |

4140 |

4459 |

4777 |

5096 |

5414 |

5732 |

|

14 |

350 |

L |

1365 |

1638 |

1911 |

2184 |

2457 |

2730 |

3003 |

3276 |

3549 |

3822 |

4095 |

4368 |

4641 |

4914 |

|

16 |

400 |

U |

1194 |

1433 |

1672 |

1911 |

2150 |

2389 |

2627 |

2866 |

3105 |

3344 |

3583 |

3822 |

4061 |

4299 |

|

18 |

450 |

T |

1062 |

1274 |

1486 |

1699 |

1911 |

2123 |

2335 |

2548 |

2760 |

2972 |

3185 |

3397 |

3609 |

3822 |

|

20 |

500 |

I |

955 |

1146 |

1338 |

1529 |

1720 |

1911 |

2102 |

2293 |

2484 |

2675 |

2866 |

3057 |

3248 |

3439 |

|

22 |

550 |

O |

869 |

1042 |

1216 |

1390 |

1563 |

1737 |

1911 |

2085 |

2258 |

2432 |

2606 |

2779 |

2953 |

3127 |

|

24 |

600 |

N |

796 |

955 |

1115 |

1274 |

1433 |

1592 |

1752 |

1911 |

2070 |

2229 |

2389 |

2548 |

2707 |

2866 |

|

26 |

650 |

S |

735 |

882 |

1029 |

1176 |

1323 |

1470 |

1617 |

1764 |

1911 |

2058 |

2205 |

2352 |

2499 |

2646 |

|

28 |

700 |

|

682 |

819 |

955 |

1092 |

1228 |

1365 |

1501 |

1638 |

1774 |

1911 |

2047 |

2184 |

2320 |

2457 |

|

30 |

750 |

P |

637 |

764 |

892 |

1019 |

1146 |

1274 |

1401 |

1529 |

1656 |

1783 |

1911 |

2038 |

2166 |

2293 |

|

32 |

800 |

E |

597 |

717 |

836 |

955 |

1075 |

1194 |

1314 |

1433 |

1553 |

1672 |

1791 |

1911 |

2030 |

2150 |

|

34 |

850 |

R |

562 |

674 |

787 |

899 |

1012 |

1124 |

1236 |

1349 |

1461 |

1574 |

1686 |

1799 |

1911 |

2023 |

|

36 |

900 |

|

531 |

637 |

743 |

849 |

955 |

1062 |

1168 |

1274 |

1380 |

1486 |

1592 |

1699 |

1805 |

1911 |

|

38 |

950 |

M |

503 |

603 |

704 |

805 |

905 |

1006 |

1106 |

1207 |

1307 |

1408 |

1509 |

1609 |

1710 |

1810 |

|

40 |

1000 |

I |

478 |

573 |

669 |

764 |

860 |

955 |

1051 |

1146 |

1242 |

1338 |

1433 |

1529 |

1624 |

1720 |

|

42 |

1050 |

N |

455 |

546 |

637 |

728 |

819 |

910 |

1001 |

1092 |

1183 |

1274 |

1365 |

1456 |

1547 |

1638 |

|

44 |

1100 |

U |

434 |

521 |

608 |

695 |

782 |

869 |

955 |

1042 |

1129 |

1216 |

1303 |

1390 |

1477 |

1563 |

|

46 |

1150 |

T |

415 |

498 |

582 |

665 |

748 |

831 |

914 |

997 |

1080 |

1163 |

1246 |

1329 |

1412 |

1495 |

|

48 |

1200 |

E |

398 |

478 |

557 |

637 |

717 |

796 |

876 |

955 |

1035 |

1115 |

1194 |

1274 |

1354 |

1433 |

|

50 |

1270 |

|

376 |

451 |

527 |

602 |

677 |

752 |

828 |

903 |

978 |

1053 |

1128 |

1204 |

1279 |

1354 |

|

52 |

1320 |

|

362 |

434 |

507 |

579 |

651 |

724 |

796 |

869 |

941 |

1013 |

1086 |

1158 |

1230 |

1303 |

|

54 |

1370 |

|

349 |

418 |

488 |

558 |

628 |

697 |

767 |

837 |

907 |

976 |

1046 |

1116 |

1186 |

1255 |

|

56 |

1420 |

|

336 |

404 |

471 |

538 |

606 |

673 |

740 |

807 |

875 |

942 |

1009 |

1077 |

1144 |

1211 |

|

58 |

1470 |

|

325 |

390 |

455 |

520 |

585 |

650 |

715 |

780 |

845 |

910 |

975 |

1040 |

1105 |

1170 |

|

60 |

1520 |

|

314 |

377 |

440 |

503 |

566 |

629 |

691 |

754 |

817 |

880 |

943 |

1006 |

1069 |

1131 |

|

62 |

1570 |

|

304 |

365 |

426 |

487 |

548 |

609 |

669 |

730 |

791 |

852 |

913 |

974 |

1035 |

1095 |

|

64 |

1620 |

|

295 |

354 |

413 |

472 |

531 |

590 |

649 |

708 |

767 |

826 |

885 |

944 |

1003 |

1062 |

|

66 |

1670 |

|

286 |

343 |

400 |

458 |

515 |

572 |

629 |

687 |

744 |

801 |

858 |

915 |

973 |

1030 |

|

72 |

1830 |

|

261 |

313 |

365 |

418 |

470 |

522 |

574 |

627 |

679 |

731 |

783 |

835 |

888 |

940 |

|

78 |

1980 |

|

241 |

290 |

338 |

386 |

434 |

483 |

531 |

579 |

627 |

676 |

724 |

772 |

820 |

869 |

*Please Note! In order to maintain your optimum saw speed, it is essential to have sufficient power driving the saw.